Rebar Couplers: A Smart Solution for Reinforcement Splicing in Modern Construction

In today’s construction industry, structural integrity, efficiency, and cost-effectiveness are critical. That’s where rebar couplers come into play—an essential technology for reinforcement splicing that ensures safe, durable, and efficient connections in concrete structures.

What is a Rebar Coupler?

A rebar coupler is a mechanical connector used to join two reinforcing bars (rebars) end-to-end. Unlike traditional lap splicing, which requires overlapping bars and consumes more material, couplers create a continuous load path that saves steel, reduces congestion, and enhances construction speed and safety.

Types of Rebar Couplers

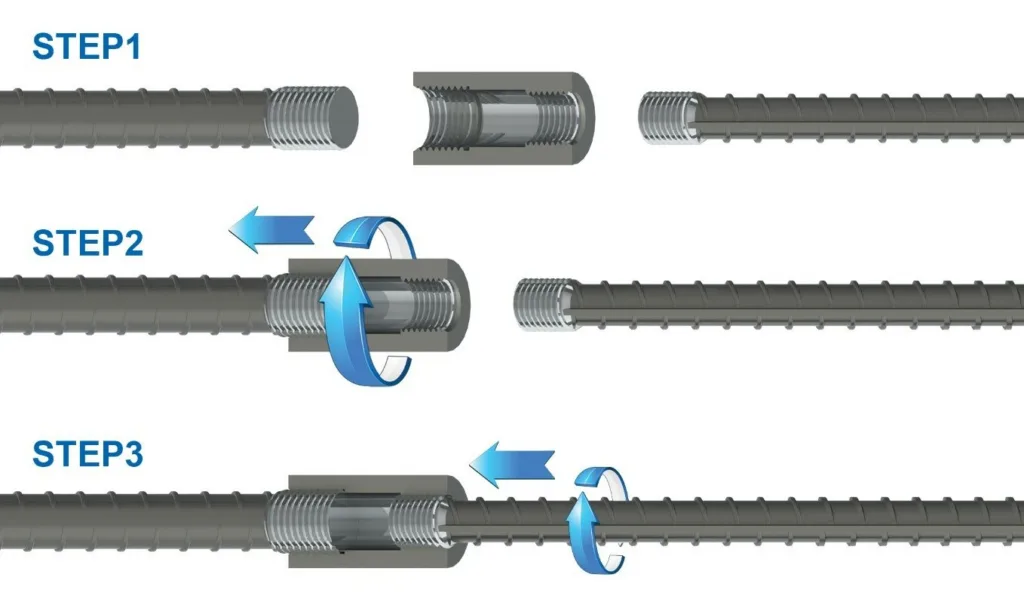

- Standard Couplers – Best for simple, in-line bar connections where both bars can be rotated.

- Position Couplers – Ideal when neither bar can be rotated during installation.

- Taper-Threaded Couplers – Feature a secure, screw-in design for quick and strong connections.

- Grout-Filled Couplers – Use high-strength grout to bond rebars, perfect for heavy load-bearing structures.

Key Benefits of Rebar Couplers

- Improved Structural Strength – Provides a continuous mechanical link, enhancing the overall structural performance.

- Material & Cost Savings – Eliminates the need for overlapping bars, reducing steel consumption and project costs.

- Faster Construction Times – Simplifies rebar placement and accelerates project timelines.

- High Versatility – Suitable for beams, columns, slabs, shear walls, and precast elements.

Where Are Rebar Couplers Used?

Rebar couplers are widely used in infrastructure and high-rise construction, including:

- Skyscrapers and multi-storey buildings

- Bridges and flyovers

- Tunnels and dams

- Industrial and marine structures

Their ability to deliver strong, reliable, and compact connections makes rebar couplers a preferred choice in projects where safety, durability, and construction efficiency are non-negotiable.

Gallery